Company

We dedicate body and soul to your project

INNOVATION

QUALITY

EXCELLENCE

Reliability

SERVICE

SUPPORT

PASSION

COMPETENCE

HOW DO WE WORK

The key to our success and the quality of our products is attention to detail at every stage of production.

The use of high-quality materials and inks selected from the best world manufacturers and our experience in the field, guarantee an impeccable final result. Our team has at its disposal the best technological resources available and is able to respond to any kind of request from your company.

MAKING ORDER

FILES ELABORATION

PRODUCTION

COMPLITION

DELIVERY

OUR TECHNOLOGIES

Cerexpo is a constantly evolving company. To ensure you always get new and better quality products, we invest in latest technologies in the printing industry, expanding our fleet of machines and constantly keeping up with the times and the needs of our customers.

OUR TECHNOLOGIES

Cerexpo is a constantly evolving company. To ensure you always get new and better quality products, we invest in latest technologies in the printing industry, expanding our fleet of machines and constantly keeping up with the times and the needs of our customers.

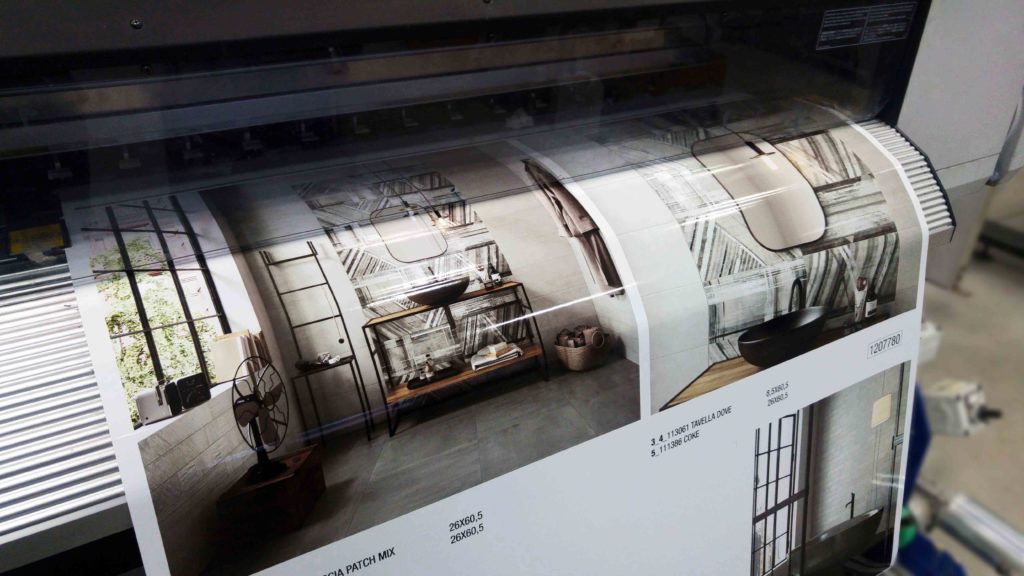

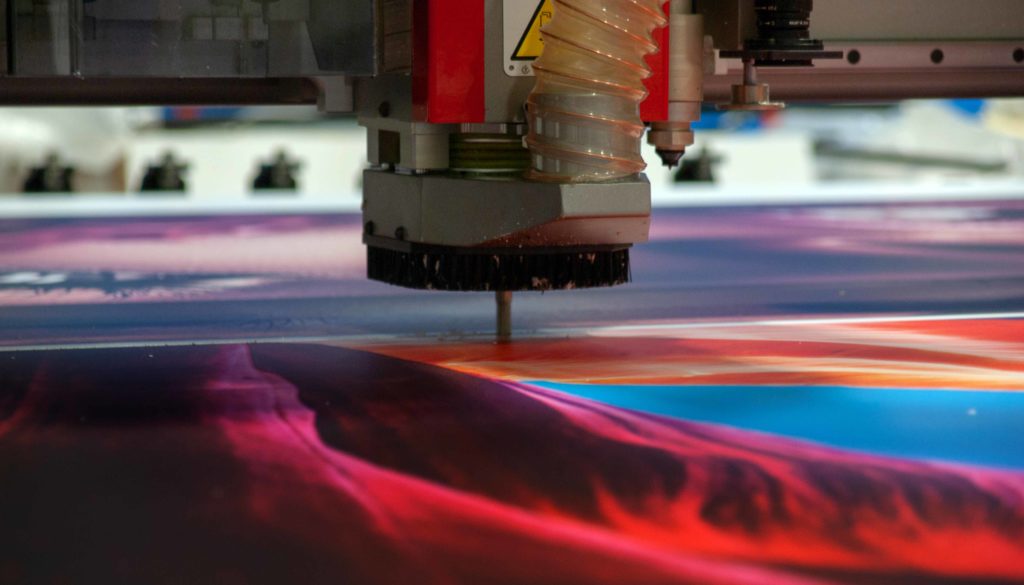

DIGITAL PRINTING

The digital printing systems that we use allow us to offer our customers printing on both opaque and glossy plastic materials, laminable with various types of lamination. We can meet any need, starting from the super glossy finish, which gives an exceptional final result to the reproduced image, concluding with the scratch-resistant lamination, which ensures greater resistance to rubbing-off. The experience and competence of our staff are the keys to the printing result, guaranteeing a quality final product.

DIGITAL PRINTING

The digital printing systems that we use allow us to offer our customers printing on both opaque and glossy plastic materials, laminable with various types of lamination.

We can meet any need, starting from the super glossy finish, which gives an exceptional final result to the reproduced image, concluding with the scratch-resistant lamination, which ensures greater resistance to rubbing-off. The experience and competence of our staff are the keys to the printing result, guaranteeing a quality final product.

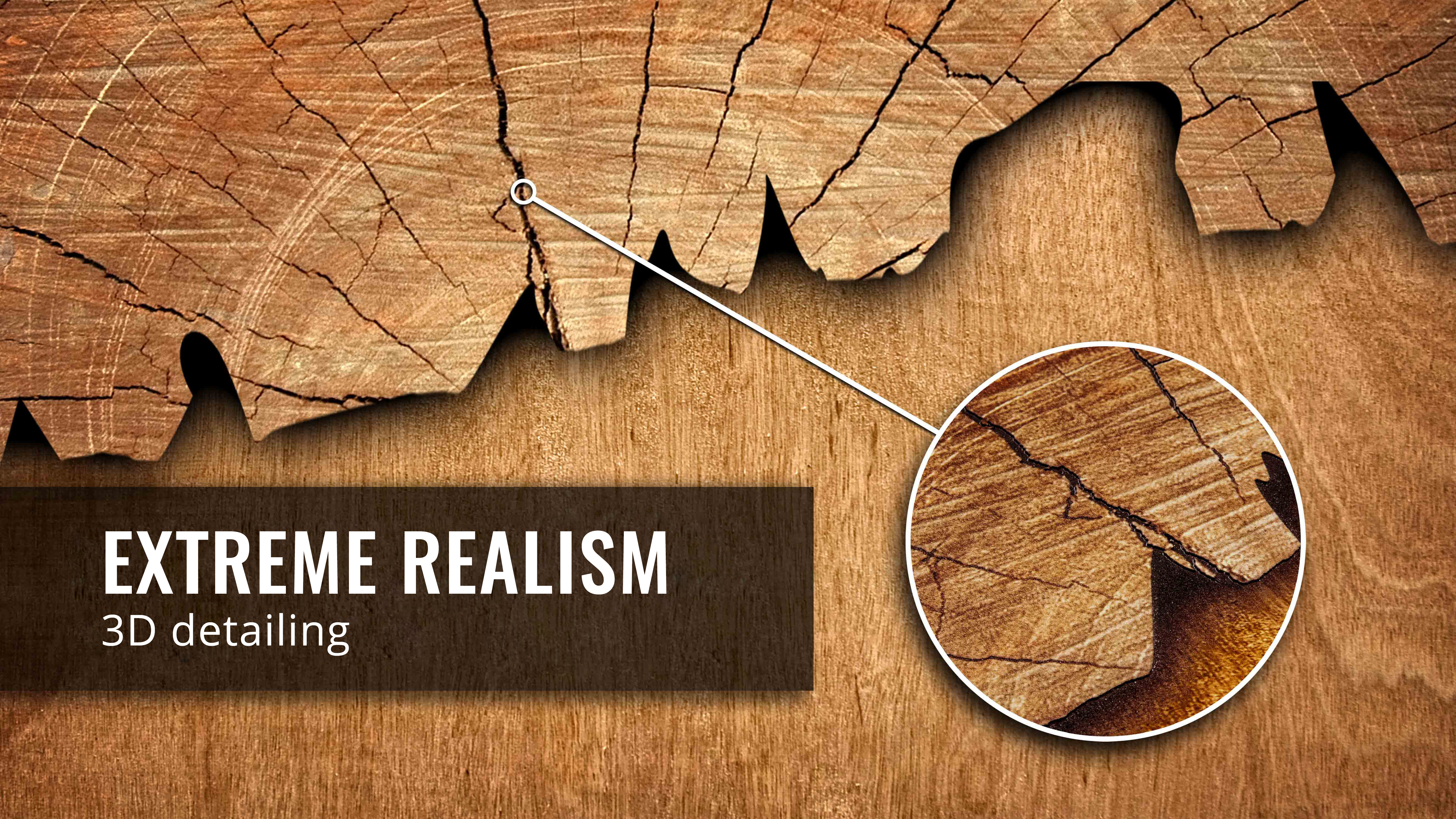

UV PRINT

UV direct printing technology is now considered to be at the forefront of our industry.

We use the best printers on the market to imprint your images on a wide range of rigid and flexible materials and even on ceramics, adding an extra touch of creativity when needed with thick machine applications. The realistic, three-dimensional effect can only be overcome by reality. In addition to ensuring quality, performance, and durability, UV printing is ecologically friendly. The use of UV inks, in fact, reduces the use of solvents that are harmful to the environment.

UV PRINT

UV direct printing technology is now considered to be at the forefront of our industry.

We use the best printers on the market to imprint your images on a wide range of rigid and flexible materials and even on ceramics, adding an extra touch of creativity when needed with thick machine applications. The realistic, three-dimensional effect can only be overcome by reality. In addition to ensuring quality, performance, and durability, UV printing is ecologically friendly. The use of UV inks, in fact, reduces the use of solvents that are harmful to the environment.

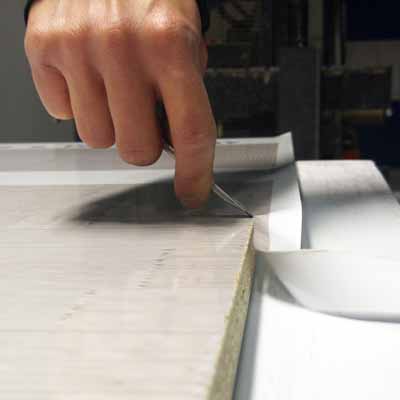

NOTCHING FLEXIBLE MATERIALS

Our digital plotters allow us to carve flexible materials for the custom realization of adhesives, labels, pre-spaced, diaphanies and many other products to be applied on any surface. The shaping makes each graphics design attractive and able to enhance the image of your project.

NOTCHING FLEXIBLE MATERIALS

Our digital plotters allow us to carve flexible materials for the custom realization of adhesives, labels, pre-spaced, diaphanies and many other products to be applied on any surface. The shaping makes each graphics design attractive and able to enhance the image of your project.

3-AXIS PANTOGRAPH MACHINING

With this CNC machine, we can carve materials of various thickness with an extreme precision and therefore overcome the limits of the shapes, enhancing the effectiveness of your creative project. Thick letters and logos represent a valid solution to expose and enhance your brand: thanks to this pantograph, we are able to perform with digital precision engravings, holes, carvings and milling on materials such as Forex®, Plexiglass®, Smart-X®, Kapa®, Dibond® and “Communication” Sandwich composite panel. The wide range of blades, saws, and cutters that can be used by our pantograph, allow us to perform a series of processes that can satisfy all your needs.

3-AXIS PANTOGRAPH MACHINING

With this CNC machine, we can carve materials of various thickness with an extreme precision and therefore overcome the limits of the shapes, enhancing the effectiveness of your creative project. Thick letters and logos represent a valid solution to expose and enhance your brand: thanks to this pantograph, we are able to perform with digital precision engravings, holes, carvings and milling on materials such as Forex®, Plexiglass®, Smart-X®, Kapa®, Dibond® and “Communication” Sandwich composite panel. The wide range of blades, saws, and cutters that can be used by our pantograph, allow us to perform a series of processes that can satisfy all your needs.

5-AXIS PANTOGRAPH MACHINING

Our new 5-axis pantograph allows extraordinary machining operations that Cerexpo has never been able to offer before. From now on we can offer exhibition equipment made with wooden, composite or plastic foamed and compact materials up to 25 cm thick. We can produce extraordinary made-to-measure displays. This CNC machine is able to import 3D CAD models and reproduce them with extreme precision. Not just cradles and displays for the ceramic industry, but also displays for any type of product, prototypes and mechanical parts in Teflon®, for example. Therefore, we offer a special solution for the processing of technological materials.

5-AXIS PANTOGRAPH MACHINING

Our new 5-axis pantograph allows extraordinary machining operations that Cerexpo has never been able to offer before. From now on we can offer exhibition equipment made with wooden, composite or plastic foamed and compact materials up to 25 cm thick. We can produce extraordinary made-to-measure displays. This CNC machine is able to import 3D CAD models and reproduce them with extreme precision. Not just cradles and displays for the ceramic industry, but also displays for any type of product, prototypes and mechanical parts in Teflon®, for example. Therefore, we offer a special solution for the processing of technological materials.